The global sachet packaging industry sees unprecedented growth. It’s driven by changing consumer preferences on convenience, sustainability, and portion control. Businesses across sectors recognize value of single – serve packaging. So understanding sachet packaging details becomes key for manufacturers, brand owners, packaging pros.

Expanding Sachet Packaging Market

Sachet packaging market is one of fastest – growing segments in flexible packaging industry. Current market valuations show a robust trajectory. Projections point to consistent expansion over next decade.

Market dynamics get shaped by key factors. These include urbanization in emerging economies, shifting consumer lifestyles, and rising demand for affordable, single – use packaging formats. Industry growth is especially notable in regions where portion – controlled packaging matches spending patterns of middle and lower – income consumer segments.

Sachet Packaging Fundamentals

A sachet is an small, single – use pouch or bag. It has sealing on three or four sides. Made to hold various products for individual consumption or application. These portable packaging solutions have user – friendly opening systems. They’re made from materials like plastic films, paper, aluminum foil, or multi – layer laminated structures.

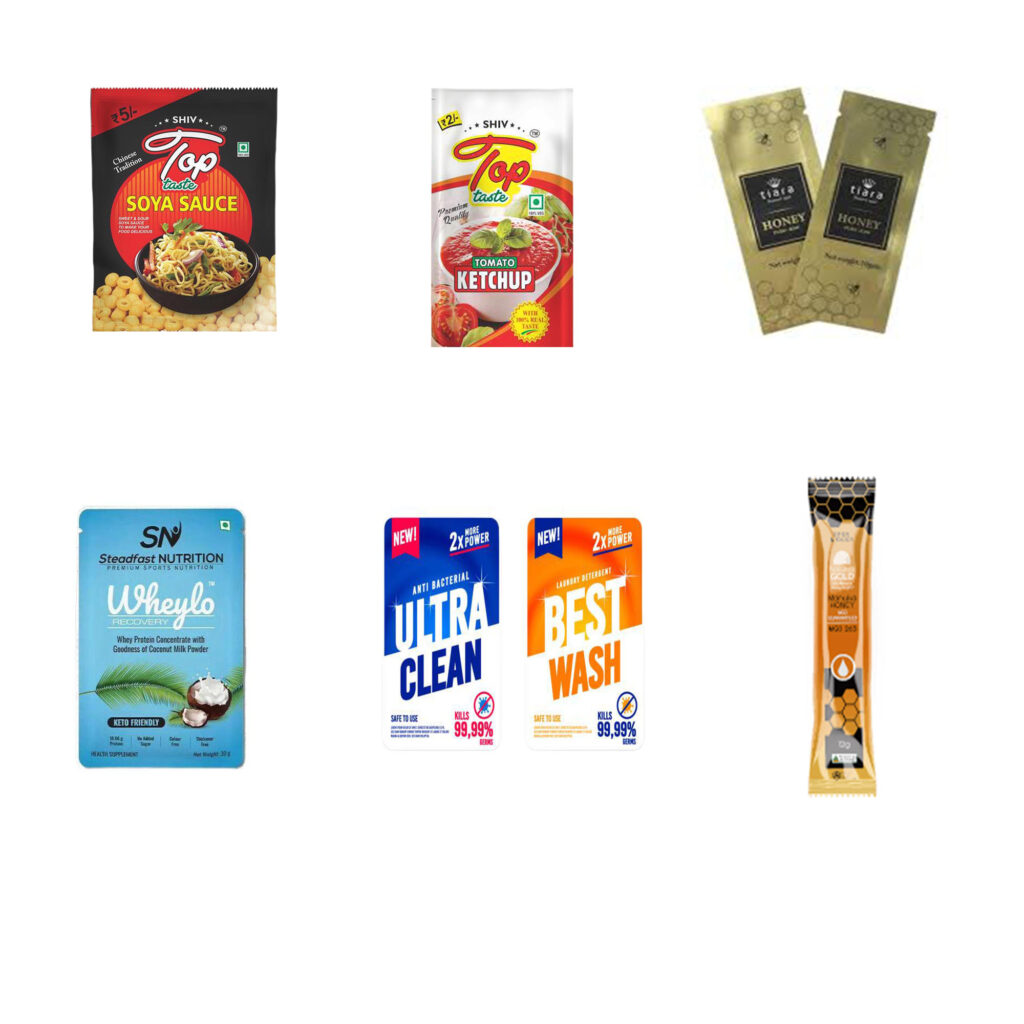

Versatility of sachet packaging lies in its ability to fit diverse product types. It also maintains product integrity, freshness, and precise portioning. This makes sachets ideal for manufacturers aiming to optimize distribution costs while meeting consumer demands for convenience and affordability.

Industry Applications & Market Distribution

Sachet packaging market serves multiple industries. Each has distinct requirements and growth patterns. Understanding these apps is crucial for businesses looking at sachet packaging solutions.

Indústria de Alimentos e Bebidas

Food and beverage sector dominates sachet packaging market. It holds the largest share of applications. This covers:

- Condiments and sauces for foodservice and retail uses

- Spices and seasonings for portion control and freshness preservation

- Instant beverages like coffee, tea, and powdered drink mixes

- Single – serve snacks and confectionery items

Pharmaceutical & Healthcare Applications

Pharmaceutical industry relies heavily on sachet packaging for precise dosing and product protection. Apps include:

- Over – the – counter medications in powder and granule form

- Dietary supplements and nutritional products

- Single – dose medications for better patient compliance

- Veterinary products for agricultural uses

Cosmetics & Personal Care

Beauty and personal care industry uses sachets for sampling and travel – sized products. Key apps are:

- Sample products for new product launches and customer acquisition

- Face masks and serums for single – use apps

- Travel – sized toiletries for hospitality and retail markets

- Hair care products in convenient, mess – free formats

Sustainable Packaging Solutions

Environmental consciousness drives big innovation in sachet packaging materials and design. Manufacturers increasingly adopt sustainable packaging alternatives to meet consumer demands for eco – friendly solutions.

Biodegradable & Compostable Materials

Modern sachet packaging uses biodegradable films and compostable substrates. These break down naturally without harming environment. Materials include:

- Plant – based polymers from renewable resources

- Compostable films that decompose within 66 – 90 days under proper conditions

- Recyclable mono – materials made for circular economy apps

Recyclable Packaging Innovation

Industry embraces mono – material structures. These help recycling while keeping necessary barrier properties. Recent innovations are:

- Recyclable homo – polymer materials that maintain product protection

- Mono – plastic structures made for existing recycling infrastructure

- Reduced carbon footprint manufacturing processes

Manufacturing Process & Technology

Producing sachets needs sophisticated machinery and precise process control. This ensures consistent quality and performance. Understanding manufacturing process is key for businesses evaluating sachet packaging solutions.

Vertical Form Fill Seal (VFFS) Technology

Vertical Form Fill Seal machines are most common for sachet production. The process has:

- Film Unwinding: Continuous rolls of packaging material feed into machine

- Tube Formation: Film is formed into a tube through longitudinal sealing

- Product Filling: Precise dosing systems dispense products into formed sachets

- Sealing and Cutting: Transverse sealing creates individual packages, then cutting

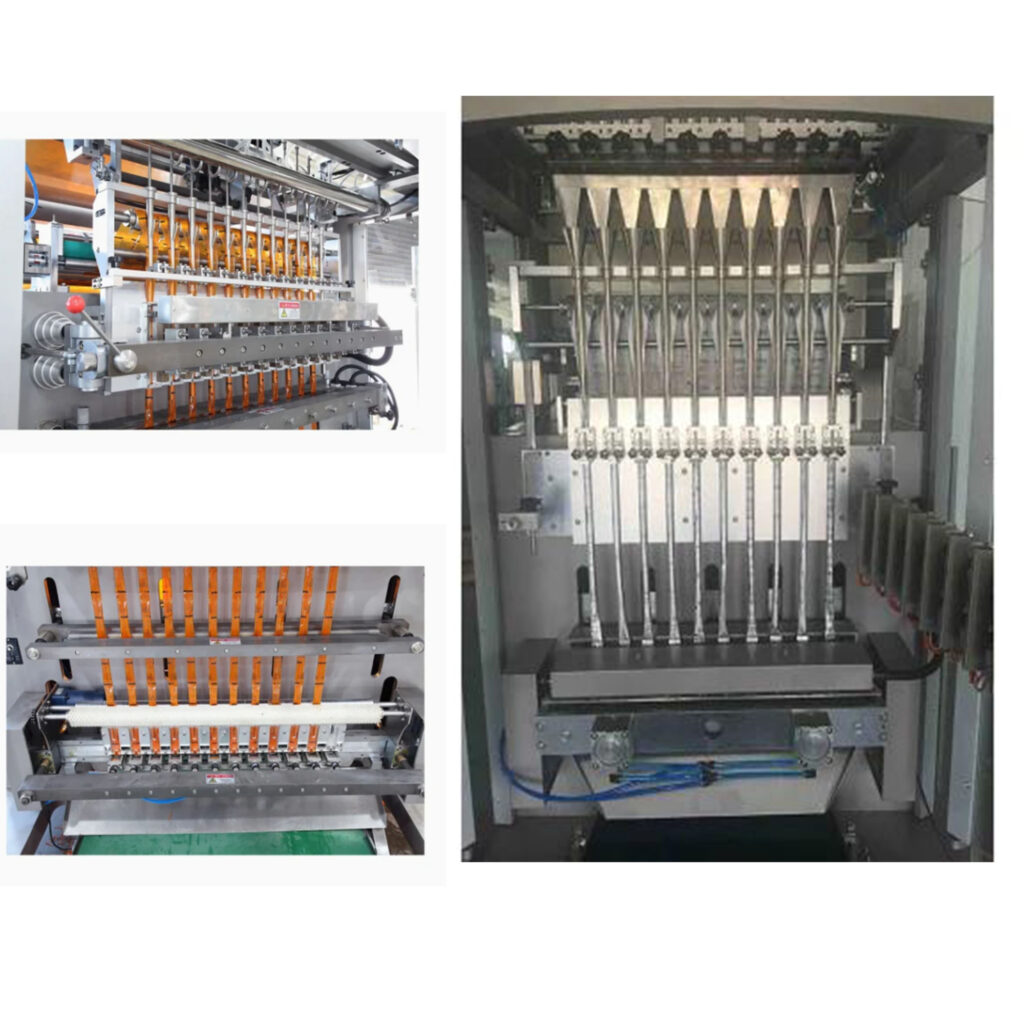

Multi – Lane Production Systems

For high – volume apps, multi – lane sachet packaging machines boost productivity and efficiency. These systems have:

- Multiple parallel production lanes for more output

- Synchronized filling and sealing across all lanes

- Flexible format changes for different product types

- Advanced quality control systems for consistent performance

Choosing Right Sachet Packaging Solution

Picking proper sachet packaging equipment needs careful thought on multiple factors. These include product characteristics, production volumes, and quality requirements.

Product Compatibility

Different products need specific filling and sealing methods:

- Powder products: Auger filling systems for accurate dosing

- Liquid products: Pump filling systems with precise volume control

- Granular products: Volumetric or weighing systems for consistency

- Viscous products: Specialized pumping systems for proper handling

Production Requirements

Volume considerations greatly impact equipment selection:

- Single – lane machines: 30 – 50 sachets per minute for smaller operations

- Multi – lane systems: 200 – 1000+ sachets per minute for high – volume production

- Flexibility requirements: Ability to handle different sachet sizes and materials

- Changeover efficiency: Quick format changes for multiple product lines

BG Machinery: Your Partner in Sachet Packaging Solutions

At BG Machinery, we understand complexities of modern sachet packaging requirements. Our wide range of packaging solutions meet diverse needs of manufacturers across industries.

Advanced Technology Portfolio

Our sachet packaging systems use cutting – edge technology for great performance:

- Servo – driven systems for precise control and consistency

- Touchscreen interfaces for intuitive operation and recipe management

- Modular designs that allow future expansion and upgrades

- Industry 4.0 integration for real – time monitoring and optimization

Comprehensive Service Support

BG Machinery gives complete lifecycle support for our packaging solutions:

- Technical consultation for equipment selection and optimization

- Installation and commissioning services worldwide

- Training programs for operators and maintenance personnel

- Ongoing technical support and spare parts availability

For detailed info on our sachet packaging solutions, visit bengangmachinery.com to explore our full product portfolio and technical specs.

Perguntas frequentes

Q: What is the minimum order quantity for sachet packaging production?

A: Minimum order quantities typically range from 10,000 to 50,000 sachets depending on the product type, materials used, and customization requirements. Máquinas BG can provide guidance on optimal order sizes based on your specific production needs.

Q: How long does it take to set up sachet packaging production?

A: Setup time varies based on complexity, but standard sachet packaging lines can typically be configured within 2-4 hours for format changes. New product development and testing may require 1-2 weeks for optimization.

Q: What accuracy can be achieved with sachet filling systems?

A: Modern sachet packaging equipment can achieve filling accuracies of ±1-2% for most powder and granular products, and ±0.5-1% for liquid products, depending on the filling system used.

Q: Can sachet packaging machines handle multiple product types on the same line?

A: Yes, flexible sachet packaging systems can handle various product types with proper changeover procedures. However, thorough cleaning between different products is essential to prevent cross-contamination.

Q: What factors affect sachet packaging costs?

A: Key cost factors include material selection, packaging complexity, production volume, customization requirements, and filling system type. Higher barrier materials and multi-lane systems increase initial investment but reduce per-unit costs at scale.

Conclusão

Sachet packaging is a dynamic and growing segment of flexible packaging industry. It offers manufacturers and brands unique chances to meet evolving consumer demands. Combo of convenience, sustainability, and cost – effectiveness makes sachets an attractive solution across industries.

Success in sachet packaging needs understanding market trends, picking right materials and equipment, and partnering with experienced suppliers. They should offer comprehensive support through product lifecycle.

At BG Machinery, we stay committed to delivering innovative sachet packaging solutions. These help our clients reach their production goals while meeting highest standards of quality and sustainability. Contact us through bengangmachinery.com to discuss how our expertise can support your sachet packaging requirements.