Thermoforming machines have revolutionized food packaging industry—they deliver cost-effective, versatile, efficient solutions for modern food manufacturers’ evolving demands. These machines turn plastic sheets into durable containers via heating, forming, cooling—they make airtight seals that keep food fresh longer. Global thermoform packaging market could hit $76.1 billion by 2034 (CAGR 3.2%)—more businesses now see value in advanced thermoforming tech.

What is Thermoforming?

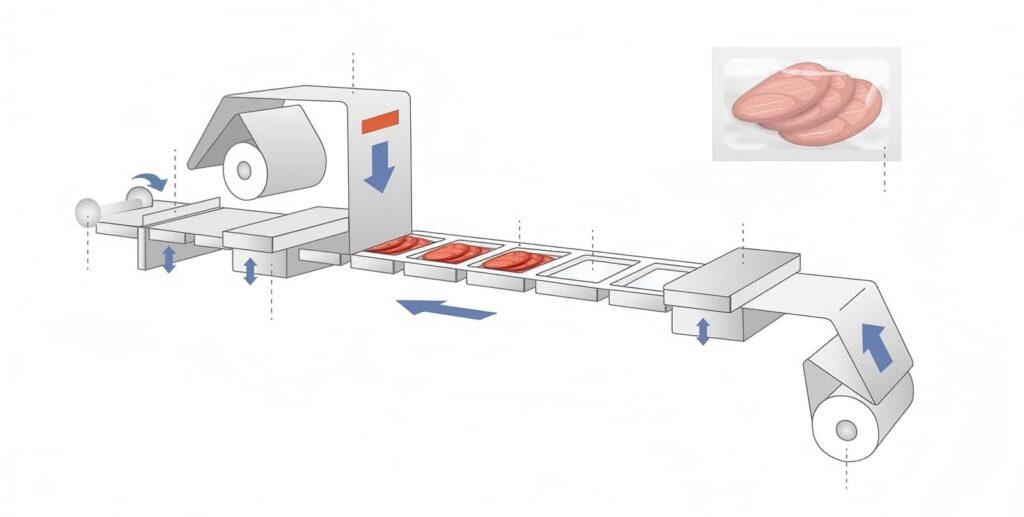

Thermoforming uses heat, vacuum, pressure to shape plastic sheets into 3D forms—molds decide the shape. First, heat a plastic sheet until it’s flexible. Then put it over a mold—vacuum or pressure makes it fit the shape perfectly. Cool it, trim the excess—now you have containers that protect food well.

How to Thermoform Food?

Thermoforming has key stages to make consistent, high-quality packaging.

First, load plastic film rolls onto machine’s roll stand—feed material through system at steady speeds. Then plastic goes through an oven—heat it to perfect temperature for molding. At forming station, molds press against heated film—shape it into container designs. Last, trim excess plastic at trim station. Inspect, stack, and get finished products ready to ship.

Benefits of Thermoforming Machines for Food Packaging

Superior Food Protection & Preservation

Thermoforming machines make sturdy containers—they keep food safe from moisture, oxygen, damage on transport and storage. Removing air from packaging slows microbes growth, prevents oxidation—this extends shelf life and cuts food waste. Airtight seals from thermoforming keep food quality and flavor—they stop moisture loss and odor absorption.

Enhanced Production Efficiency & Cost-Effectiveness

Modern thermoforming machines boost production efficiency and cut costs—they’re a efficient choice for businesses. Molds cost less than injection molding—upfront tooling expenses drop 50-70%. High-speed production lets manufacturers make lots of units fast—some machines do 500 per hour. Automation cuts labor needs—still keeps product quality consistent.

Design Flexibility & Customization

Thermoforming lets manufacturers make packaging in all shapes and sizes—great for different products. Quick mold changes and easy customization mean less downtime—perfect for businesses that change packaging often. This versatility works for standard and specialized packaging—across many food types.

Your Trusted Packaging Partner –BG Machinery

Since 2008, BG Machinery has been a top manufacturer and supplier of filling and packaging equipment—we serve food, non-food, cosmetic, pharmaceutical industries worldwide. Based on Ruian City, Wenzhou, China, we’ve changed packaging equipment industry—we offer one-stop solutions to boost clients’ efficiency and productivity.

Our Commitment to Excellence

At BG Machinery (bengangmachinery.com), we offer superior packaging solutions—like pouch machines, vertical and horizontal form fill seal machines. Our experienced engineers give free technical support, layout services, and training—all to make sure equipment works its best. We have dozens of repair centers worldwide and 12-month warranties on all equipment—we’re committed to customer satisfaction and reliability.

Comprehensive Service Portfolio

Our services go beyond manufacturing—we offer turnkey solutions, consulting, equipment qualification, and professional maintenance. We use top-quality wooden crates for safe shipping. Modular components cut downtime—we even include 2-3 spare sets for emergencies before dispatch. This approach means clients get more than just equipment—they get complete packaging solutions made for their needs.

Food Safety & Regulatory Compliance

Regulatory Requirements

Thermoforming for food packaging needs to follow strict safety rules—protect consumers. US uses FDA rules for food contact materials. Europe follows EFSA standards. Regulation (EC) No 1935/2004 says materials can’t release harmful stuff into food—must keep traceability in supply chain.

Quality Assurance Standards

Food-grade thermoforming needs BRC accreditation—rigorous quality testing all through production. Manufacturers need HACCP and GMP—keep product safety consistent. Use approved food-grade materials like PET, PP—key for compliance and consumer safety.

Frequently Asked Questions About Thermoforming Machines

What types of food products can be packaged with thermoforming machines?

- Fresh meat and poultry

- Seafood and fish

- Cheese and dairy products

- Bread and baked goods

- Ready meals and prepared foods

- Fruits and vegetables

- Pet food

- Snacks and confectionery

- Deli products

How much does a thermoforming machine cost?

- Entry-level machines: $20,000-$50,000

- Mid-range machines: $50,000-$100,000

- High-end industrial machines: $100,000-$500,000+

- Used machines: €10,000-€150,000 ($11,000-$165,000)

What are common problems with thermoforming machines?

- Heating inconsistencies

- Mold defects and wear

- Vacuum system failures

- Material feed problems

- Cooling issues

- Temperature control problems

- Pressure insufficiency

How often should thermoforming machines be maintained?

- Daily: Visual inspection, lubrication, temperature checks

- Weekly: Cleaning of heating elements and molds

- Monthly: Comprehensive mechanical inspection

- Quarterly: Detailed system calibration

- Annually: Complete overhaul and part replacement

What materials can be used in thermoforming?

- PET (Polyethylene Terephthalate)

- PP (Polypropylene)

- PS (Polystyrene)

- PLA (Polylactic Acid)

- CPLA (Crystallized PLA)

- APET (Amorphous PET)

- Various food-grade plastics

How fast can thermoforming machines produce packages?

Production speeds vary by machine type:

- Entry-level: 3-6 cycles per minute

- Mid-range: 4-10 cycles per minute

- High-speed machines: Up to 40 cycles per minute or more

- Industrial machines: 500+ units per hour

What safety regulations apply to thermoforming food packaging?

- FDA regulations (United States)

- EFSA standards (Europe)

- BRC accreditation requirements

- HACCP compliance

- Good Manufacturing Practices (GMP)

- Food contact material regulations

Is thermoforming environmentally friendly?

- Uses recyclable materials

- Reduces material waste through precision forming

- Leftover material can be reprocessed

- Energy-efficient modern machines

- Supports circular economy principles

- Lower carbon footprint than some alternatives

Conclusion

Thermoforming machines are a smart investment for food packaging—boost efficiency, cut costs, improve quality. Design flexibility, cost-effectiveness, great food protection—perfect for modern packaging challenges. Market demand grows, sustainability rules get stricter—thermoforming will play an increasingly important role in food packaging.

BG Machinery is here to help with your thermoforming needs—comprehensive solutions, expert support, reliable after-sales service. We’re committed to innovation and customer success—your thermoforming investment will give long-term value and competitive edge. Contact us today to see how our solutions can transform your packaging and grow your business.