- Home

- Granule Packaging Machine

- Rice Packing Machine

Rice Packing Machine

Custom Packing Machine for Rice

BG Machinery Packing Machine offers a wide range of rice machines, providing various solutions for your rice packing needs.

With decents years of custom experience, BG Machinery enables it to offer various innovative packing solutions through its Vertical Stickpack Machine , VFFS Machine, and HFFS Machine manufactured with your needs.

- International components, 99.99% accuracy, 360-1500bags/h speed.

- High precision, stable function, digital display, easy operation.

- Auto-adapted software controls setup, fall height correction, alarms.

- Versatile platform, wide range, raised/lowered for efficiency.

- Imported sensors, pneumatic mechanism ensure reliability

- Easy Maintenance: Simplified upkeep minimizes downtime.

- Customizable Packaging: Adjustable settings meet diverse needs.

Rice Packing Machine for Sale

1 kg Pouch Packing Machine

This machine is designed for small-scale packaging, ideal for packing 1 kg pouches. It typically uses heat-sealing methods and include options for vacuum packing.

5 kg Pouch Packaging Machine

Slightly larger than the 1 kg machine, this is designed to handle 5 kg pouches. It likely shares similar technology (such as heat sealing) but has a larger capacity and potentially faster throughput.

Vertical Form Fill Seal Machine for 10 kg Rice

This machine automates the process of making, filling, and sealing the pouch all in a vertical fashion. It's specifically calibrated for 10 kg of rice, making it ideal for medium-scale rice packaging.

25 kg Rice Packaging Machine

Designed for larger quantities, this machine use a different mechanism (like big filling equipment) suitable for heavier 25 kg bags.

50 kg Rice Packing Machine

This is the largest scale among the ones listed, suitable for industrial-grade packaging of 50 kg rice bags. This machine include advanced features like heavy-duty conveyors and bulk handling systems.

Video Gallery

RIce Packaging Machine Video

Skyrocket Your Business with BG Machinery

How can we order the right machine?

How can we check your machine quality after we place an order?

You will receive photos and videos of the machine every 5-10 days so that you can assess its running condition. In addition, you’re welcome to check the machine by yourself at our factory.

Why we should choose you?

- Professional team 24 hours provide service for you

- 12 months warranty

- Life time technical support no matter how long you have bought our machine

- Oversea service is available.

What about your payment?

T/T by bank account directly L/C at sight

Ultimate Guide

Rice Packaging Machine : The Complete Guide 2025

Table of Contents

Rice packaging machine is a specialized machine used in the food industry to package various types of grains, such as paddy, coffee beans, peanuts, wheat, and sunflower seeds. The Bengang Machinery rice packaging machine has the function of automatic filling, weighing, sealling. It’s equipped with a conveyor and bag sealing machine, with high packing precision and speed, it’s widely used in modern rice mill plant.

What is the Type of Rice Packaging Machine?

There are several types of rice packaging machines available in the market, each catering to meet different packaging needs. Some common types include vertical form-fill-seal machines, automatic bagging machines, and multi-head weighers. The choice of machine depends on factors such as packaging speed, bag size, packaging material, and desired level of automation.

Vertical Form Fill Seal (VFFS) Machines

Vertical form fill seal machines are a popular choice for packaging rice efficiently. They form bags from a roll of packaging film, fill them with rice, and seal them vertically. VFFS machines are known for their high-speed operation, making them ideal for large-scale rice production facilities. They offer flexibility in bag sizes and can accommodate various packaging materials.

Rotary packaging machines are versatile solutions suitable for packaging rice in preformed bags. These machines feature a rotating carousel that moves bags through different stations for filling, sealing, and labeling. Rotary packaging machines offer high precision and can handle different bag styles, such as pillow bags and gusseted bags, catering to diverse packaging requirements.

Weighing and Filling Machines

Weighing and filling machines are designed to accurately measure and fill rice into bags or containers. These machines utilize advanced weighing technology to ensure precise measurement, minimizing product giveaway and maximizing efficiency. They are often equipped with automatic feeding and packaging functions, reducing manual labor and increasing productivity.

Auger Filling Machines

Auger filling machines are specifically designed for packaging powdered or granular products like rice. They feature a rotating auger screw that dispenses a controlled amount of rice into bags or containers. Auger filling machines are suitable for both free-flowing and non-free-flowing rice varieties, offering versatility in packaging options.

Vacuum Packaging Machines

Vacuum packaging machines remove air from bags or pouches before sealing, extending the shelf life of rice by preventing oxidation and spoilage. These machines are ideal for packaging rice in vacuum-sealed bags, preserving freshness and flavor. Vacuum packaging also helps prevent insect infestation and moisture absorption, ensuring product quality during storage and transportation.

Combination Weighing and Packaging Systems

Combination weighing and packaging systems combine multiple weighing units with packaging machinery to achieve high-speed and accurate rice packaging. These systems use sophisticated algorithms to distribute rice evenly into individual packages, optimizing efficiency and reducing product waste.

Automatic Bagging Machines

Automatic bagging machines streamline the packaging process by automatically forming, filling, and sealing bags without manual intervention. These machines are equipped with advanced controls and sensors to ensure consistent and reliable packaging results. Automatic bagging machines are suitable for large-scale rice packaging operations, offering high throughput and efficiency.

What is the Benefits of Automatic Packaging Machine?

- Packaging machines finds diverse applications across various industries, including food, chemical, pharmaceutical, and light sectors, with some involvement in agricultural production.

- These machinery offer ease of operation by automating bag creation, measuring, filling, sealing, cutting, counting, batch printing, and other essential functions.

- Remarkable efficiency characterizes packaging machinery in the international market, with output rates reaching up to 120-220 packs per minute. This marks a significant leap from manual production methods of the 1980s, multiplying productivity several times over.

- Emphasizing cleanliness, hygiene, and energy conservation, packaging machines eliminate the need for manual labor, ensuring a hygienic production environment. They also contribute to material conservation, cost reduction, and environmental sustainability.

- Equipped with side-opening protective baffles, these machines prioritize operator safety while providing clear visibility during operation, ensuring a secure working environment.

- Versatile customization: Packaging machinery can be tailored to meet specific production requirements, offering flexibility in packaging design, size, and material.

- Advanced Control Features: Modern packaging machines often come with advanced control systems, allowing for precise adjustment of packaging parameters and seamless integration into automated production lines.

What is the Rice Packaging Process?

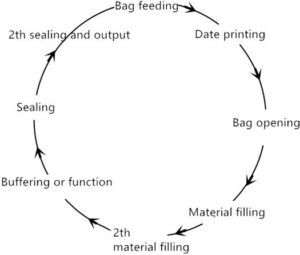

There are three stages to the whole weighing process: fast feeding, faster feeding, and slow feeding. This equipment can also be equipped with automatic sealing and conveying equipment to form a highly automated production line.

After the packaging scale switches to automatic mode, the weighing control system initiates feeding by opening the feeding door. This device offers fast and slow feeding stages: the fast feeding halts when the material hits the preset weight, transitioning to slow feeding. Upon reaching the final weight, the feeding door closes, completing dynamic weighing. Simultaneously, the system checks if the bag clamping device is ready; upon confirmation, it signals to open the weighing hopper discharge door, allowing material into the bag. Once discharged, the hopper door closes automatically, releasing the bag clamping device, and the bag descends for sewing and onward transportation. This seamless cycle operates automatically for efficiency.

Rice VFFS Machine vs. Rice Pouch Packing Machine: Which Is Better?

| Feature | VFFS Machine | Pouch Packing Machine |

|---|---|---|

| Throughput | 100–180 packs/min | 50–100 packs/min:cite[3] |

| Material Flexibility | Compatible with recyclable films | Ideal for pre-made pouches |

| Cost | Higher initial investment | Lower upfront costs |

| Customization | Limited to vertical bags | Supports diverse pouch designs |

Vertical Form Fill Seal Machine for Rice: For some rice producers who need to change packaging specifications frequently and have a variety of packaging styles, vertical form fill seal machine is a better choice. For example, some of the main high-end customized packaging of rice brands, will often adjust the size, shape and pattern of the bag according to customer demand, vertical forming filling and sealing machine can well meet these needs.

Rice bagging packaging machine: If the enterprise’s rice product packaging specifications are relatively stable, the output is larger, then the efficiency of the rice bagging packaging machine will be higher. For example, some large rice processing enterprises, the production of rice is mainly 5kg, 10kg and other fixed specifications, bag packing machine can quickly complete a large number of packaging tasks.

VFFS machines excel in high-volume settings, while pouch systems are better for premium, branded packaging

What Types of Rice Can Be Packaged Using Automatic Packaging Machines?

Automatic rice packaging machines are incredibly versatile and can handle a wide variety of rice types, including:

- Long Grain Rice: Such as basmati and jasmine rice.

- Medium Grain Rice: Such as sushi rice and Arborio rice.

- Short Grain Rice: Such as glutinous rice and sweet rice.

- Brown Rice: Whole grain rice with the bran layer intact.

- Parboiled Rice: Rice that has been partially boiled in the husk.

- Wild Rice: Technically a grass seed, but often categorized with rice.

- Specialty Rice Blends: Mixtures of different rice types.

The machine settings can be adjusted to accommodate the specific characteristics of each rice type, ensuring optimal packaging quality.

What are the Specific Considerations for Packaging Different Rice Sizes (e.g., Long Grain, Short Grain, Basmati)?

Packaging different rice sizes requires specific considerations to ensure optimal results:

- Long Grain Rice (e.g., Basmati): Due to its slender shape, long-grain rice can be prone to breakage during packaging. Gentle handling and precise filling are essential.

- Short Grain Rice (e.g., Sushi Rice): Short-grain rice tends to be stickier than long-grain rice. Choose equipment that prevents clumping and ensures consistent flow.

- Medium Grain Rice: Requires a balance between gentle handling and efficient filling.

- Broken Rice: Broken rice is prone to sifting and leakage. Use packaging materials with fine seals and consider inner liners.

Proper adjustments to the machine’s filling and sealing mechanisms can significantly reduce product damage and ensure accurate packaging.

How To Selecting a Rice Packaging Machine ?

When selecting a rice packaging machine, prioritize these key features:

- Speed and Efficiency: Opt for high-speed machines capable of efficiently handling large volumes of rice.

- Accuracy: Ensure precise weight measurements for consistent packaging quality.

- Packaging Material Compatibility: Confirm compatibility with your chosen packaging materials, be it plastic bags or laminated pouches.

- Ease of Use and Maintenance: Choose a user-friendly machine with minimal downtime for maintenance and cleaning.

- Durability and Reliability: Consider the build quality and reliability reputation to ensure uninterrupted operation and longevity.

- Safety Features: Prioritize machines equipped with essential safety features to protect operators and prevent accidents.

Additionally, select a rice packaging machine from a reputable manufacturer like Lintyco , known for offering after-sales support, spare parts, and technical assistance.

Takeaways

Now that you understand the different types of coffee packaging machines and process of bagging rice, it’s important to select the right machine for your business.

So, which type of rice packaging machine is best for your business? That answer depends on the products you are looking to package and the level of automation you need.

If you are unsure which machine would be a good fit for your company, Contact Bengang Machinery.

At Bengang Machinery, we can help you in finding the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions you may have about selecting the right rice packaging machine for your business.

Contact us today to get started!

Want to Get Rice Packing Machine Price?

Why We're Different